Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

Fish farming or aquaculture is becoming a significant industry globally, contributing to the world supply of fish and seafood. Farmers must provide adequate nutrition to the fish, and this is achieved through feeding. Two common ways to supply fish feed are through the use of dry fish feed machines and wet fish feed extruders. In this article, we explain the differences between the two types of machines and what they entail.

A dry fish feed machine is a device that turns raw materials, such as soybean meal, corn, wheat, and fishmeal, into dry pellets. The device is used to prepare food for fish, shrimp, and pets like rabbits and dogs. It typically produces hard and dense pellets of about 2mm to 10mm in size.

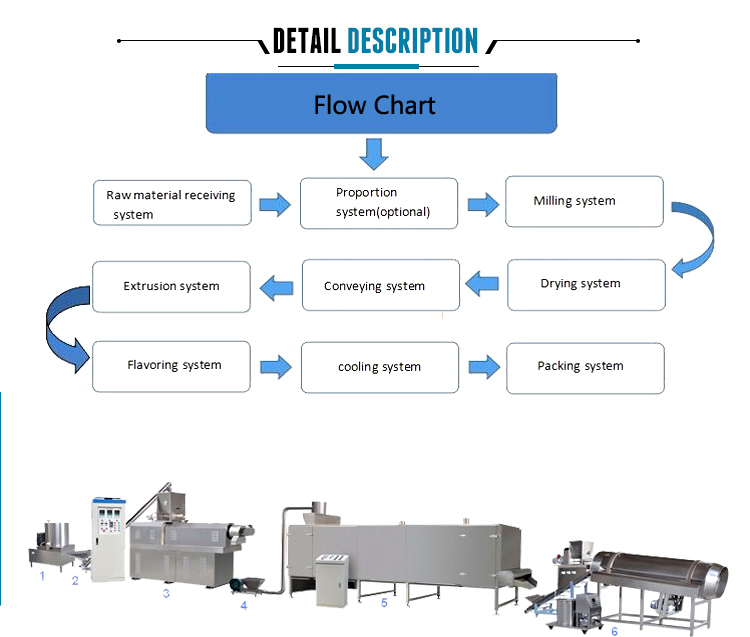

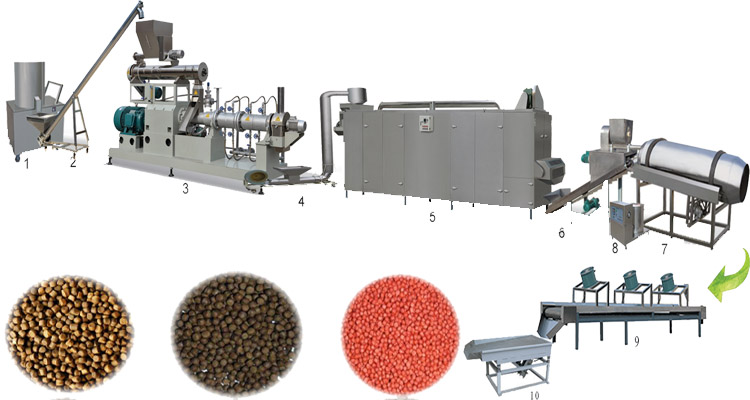

The process for producing dry fish feed consists of four main steps:

1. Grinding: This step involves grinding the raw materials into fine powder using a grinding machine.

2. Mixing: The process of mixing raw materials involves combining the powdered materials in a mixer, adding water and oil to the mixture. This process aims to make the food more nutritious and digestible for the fish.

3. Pelletizing: The pelletizing machine compresses the mixed powder into pellets. The final pellets undergo drying to remove moisture and give them a more extended shelf life.

4. Cooling and Packaging: After drying, the pellets cool down and then packaged for transportation and storage.

The dry fish feed machine is popular among fish farmers because of the benefits it offers. First, the pellet is easy to store and transport. The food can be made in bulk and can last for months, taking up less storage space compared to wet feed. Additionally, the pellets are less susceptible to contamination from bacteria or fungi, reducing the risk of disease transmission.

The machine is less expensive compared to the wet extruder, making it more accessible to smaller fish farmers with limited resources. However, the dry fish feed machine has some limitations. The mineral and vitamin content in the pellets may be reduced by the drying process. The machine can also produce pellets with low density, which are less nutritious for fish. Furthermore, the pellets may be difficult for fish to digest, leading to wastage.

A wet fish feed extruder is a machine that uses heat, pressure, and steam to produce feeds. The materials used in the process are the same as those used in the dry fish feed machine, but in the wet fish feed extruder, water is added to the mixture, creating a wet dough-like mixture.

The process of producing wet fish feed involves several steps:

1. Grinding: Similar to the dry fish feed machine, raw materials are crushed into fine powder.

2. Mixing: Water is added to the powdered materials in a mixer to create a dough-like mixture.

3. Extrusion: The extruder machine works on the dough-like mixture by feeding it through a barrel with a screw. The screw's rotation and heat from the barrel create pressure that squeezes the mixture through the small holes in a die. The mixture then undergoes expansion and shaping, and it cools down after passing through the die.

4. Drying: The final product still contains moisture and undergoes heating and drying to remove moisture, improve shelf-life and stability.

5. Cooling: After drying, the final product cools, and then it's packaged.

The wet fish feed extruder has some advantages. As the feed extruder produces a wet pellet, it's easier for fish to digest than the dry pellet. The wet fish feed machine can also produce pellet types with varied sizes and shapes, which can suit the fish's preferences. Furthermore, the machine produces food with higher nutritional value, which can boost fish growth rates.

However, the wet fish feed extruder also has some disadvantages. The feed is not long-lasting and can spoil quickly, making it challenging to store and transport. Additionally, the wet fish feed machine is costly to set up and maintain, making it unaffordable for small fish farmers or hobbyists.

Comparison of the two machines

Both machines complement each other. The dry fish feed machine is more affordable, and the pellets are easier to store and transport. On the other hand, the wet fish feed extruder is more nutritious, and the fish find it easier to digest, leading to less wastage. Therefore, it's up to the fish farmer to determine which machine best suits their farm's needs.

Conclusion

In summary, fish farming is an essential global industry that requires adequate feeding to boost fish growth rates. Dry fish feed machines and wet fish feed extruders are two popular feed preparation machines used in fish farming. The dry fish feed machine is cost-effective, and pellets are more comfortable to store and transport. However, it produces food with lower nutritional value and with higher wastage rates as fish digestion may be challenging. The wet fish feed extruder is more nutritious, easier for fish to digest, with less wastage. Still, it's more costly to set up and maintain, with storage and transportation challenges. Fish farmers must choose which machine best suits their farm's needs based on the fish they produce and the farm's resources.

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.