Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

1.Pet food processing line Brief introduction:

1). Dog production line is widely used for producing grains into highgrade aquatic feed pellets for dog, catfish, shrimps, crab etc.

2). We provide basic dog food formula according to your require.

3). The final dog food shapes and sizes can be various by changing the mould.

4). We support private customization.

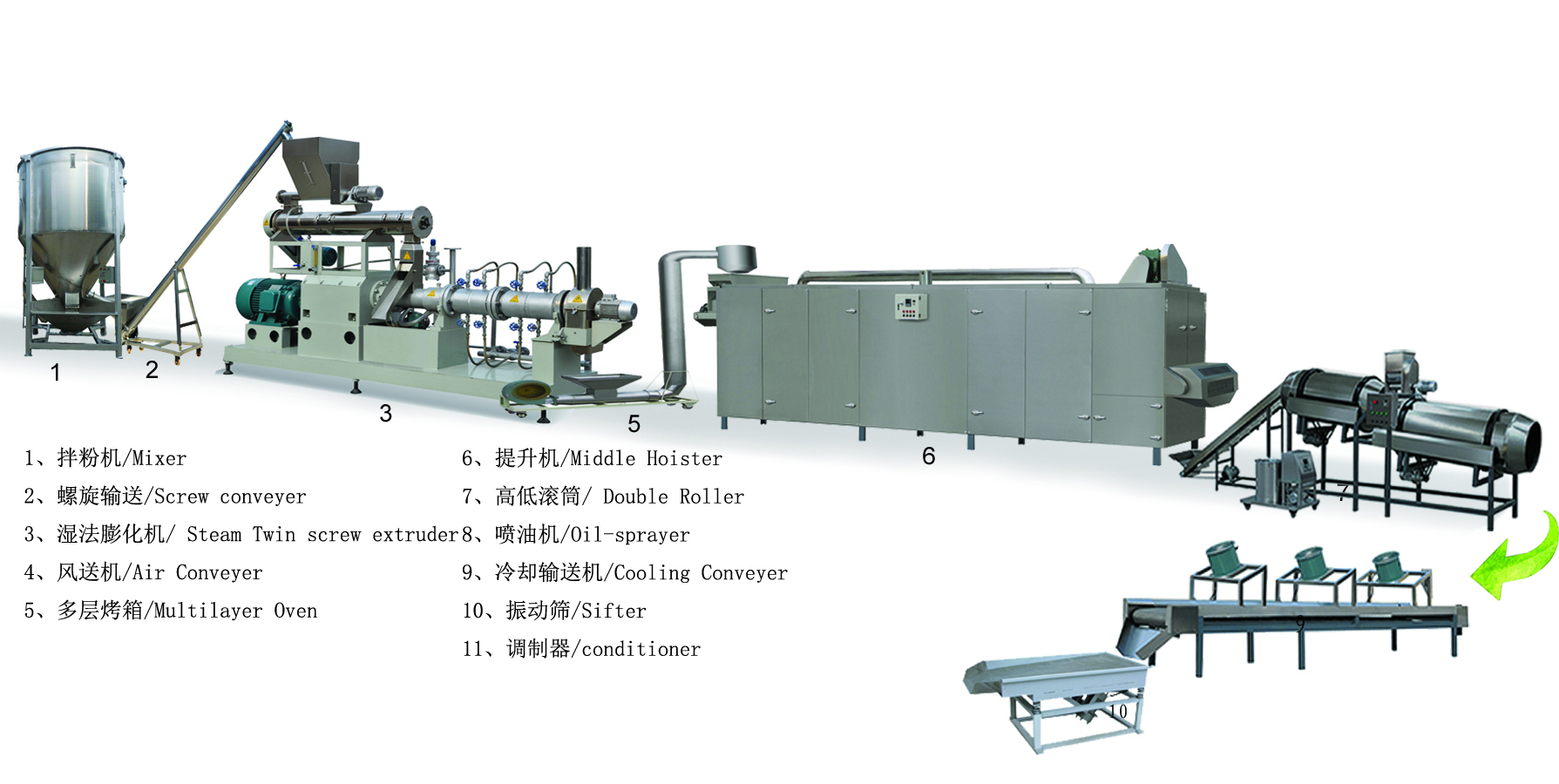

2.Pet food processing line Configuration:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

3.Machine Parameter

Model Number: | SLG65/70/85/90/95/115/120 | Application: | Dog Cat Monkey Pet |

Voltage: | 208/220/240/380/400/415/440/480V | Power(W): | As per final configuration or user requirement |

Weight: | As per final configuration or user requirement | Dimension(L*W*H): | As per final configuration or user requirement |

Certification: | ISO, CE, SGS, BV | Warranty: | 1 year |

After-sales Service Provided: | Engineers available to service machinery overseas | Dog feed raw materials: | Corn meal, wheat flour, rice flour de-oil soya flour, etc. |

Capacity: | 100-5000kg/hr | Heating power source: | Electricity, oil-fired burner,gas-fired burner, steam |

Screws quantity: | 1 couple (twin-screw) | Screws material: | 38CrMoAl |

Fish feed diameter: | From 1.5mm to 25mm | Dies | 6 pcs for free |

Inverter brands: | Delta, LS, ABB, Siemens, customizable | Motor brands: | Siemens |

4.Jinan FLD Machinery Company

(1) Provide variety models of twin-screw extruders and supporting ingredients, drying, tabling, baking, spraying, frying machines.

(2) Achieved equipment independent design and production, obtained a number of patents, successfully realized the grains products Extension and promotion of nutrition, rice, breakfast cereals, kinds of fried, non-fried snack foods, high molecular tissue proteins, brush tissue protein, instant porridge, instant rice and other fields.

(3) Provide complete food twin-screw extrusion technology engineering demonstration center, it can provide users with a multifunctional scientific research demonstration platform for food production equipment, technology, formula development and application, fully bridge the integration of production, learning and research, function, reduce the investment risk of customers, promote the application of extrusion technology in grain food processing and create value for customers.

(4) The scope of participation in food engineering projects includes the following: it enables us to provide our customers with a complete set of project solutions based on the specific requirement of our customers, and to propose, plan, design and project food plants to suit your budget and specific production needs.

(5) Complete turnkey system for crushing mixing systems, micro-component dosing systems, extrusion drying systems, and spray coating systems.

(6) Central centralized control system, whole plant automation engineering.

(7) Complete peripheral equipment: electrical installation, automation, pneumatic and liquid applications, civil engineering for turnkey projects.

(8) Application include breakfast cereal cornflakes, ready-to-eat rice nutrition rice series, protein, tissue protein, snack foods, pet food, aquatic feed, etc.

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.