Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

1.Pasta Macaroni Production Line Introduction:

Automatic Short Cut Pasta Macaroni Producing Machine Line is equipped with mixer, conveyor, extruder, cooling conveyor, hoister and dryer. It has been researched and developed for almost ten years thus has the features of high automation, durable machine parts, visible temperature control and so on. Within these advantages, the shot cut pasta macaroni machine has become welcomed in the market. The short cut macaroni can be shaped in various shapes, such as shell, fusilli and so on.

2.Technical Parameters:

Model | Install Power | Real Power | Capacity | Dimension | Delivery |

DLG110 | 105KW | 73KW | 120-150kg/h | 22x 2.0 x 3.0 | 35 |

DLG150 | 190KW | 135KW | 250-300kg/h | 30x 2.0 x 3.0 | 40 |

DLG160 | 250KW | 175KW | 350-400kg/h | 35x 2.5 x 4.2 | 55 |

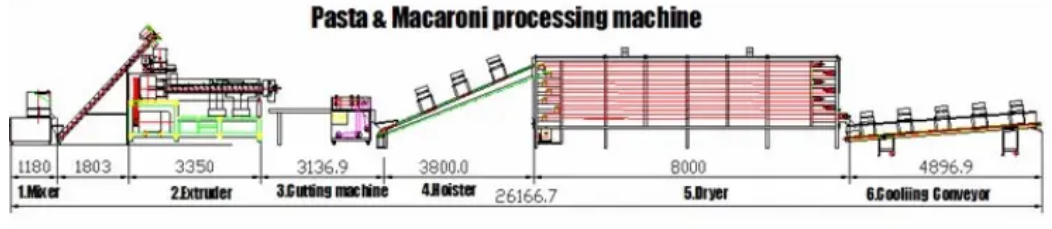

3.Macaroni food processing line Flow Chart

Pasta Macaroni Manufacturing Equipment Machine Line is researched and developed in advanced technology and high automation with decades years, which satisfies the demand of easy operation and stable performance. With different mould, the products can be made in various shapes, such as shell, conchiglie, penne, fusilli and so on.

Mixing system---Extrusion system----Cutting system---Drying system---Cooling system--Packing system

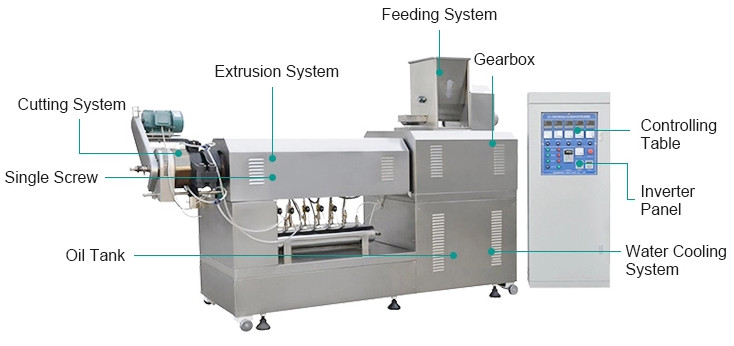

4.Pasta Macaroni Production Extruder Details:

1.Feeding System:Installed in the main machine, which feeds materials spirally, and the quantity can be adjusted. This system includes engine, screw, blender and machine shelf.

2.Extruding System:Adopts the crafts what can make the materials ripe in the low temperature by blending, cutting and extruding. Temperature control is set strictly on the roller and screw to reach criteria the materials require.

3. Cutting System:The shelf is fixed on the head of the moulds; and turns and cuts the materials motivated by the belt wheel.

4.Heating System:Divides five areas, and the heating temperature of which can be adjusted separately.

5.Transmitting System:The motive power from the main engine is transmitted to the screw through the triangle belt and decelerator.

6.Controlling System:Can control all the components of the main machine centrally.

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.