Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

Introduction

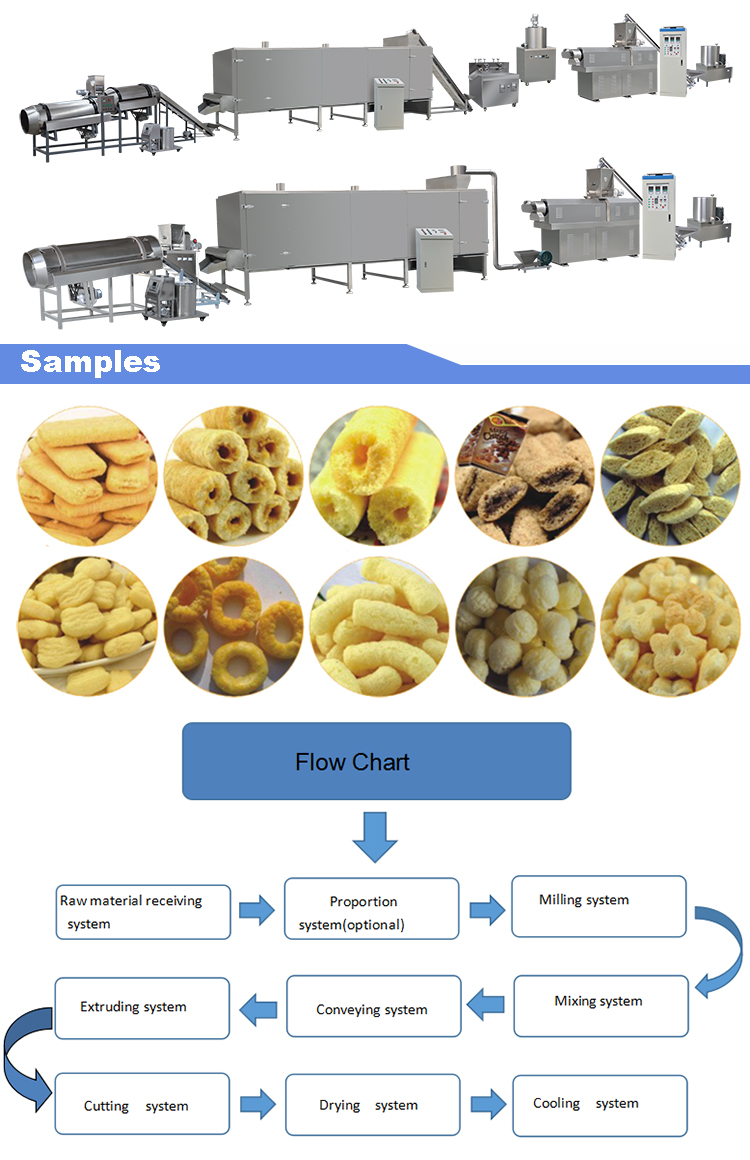

FLD Company Puff Snack Machine can produce all kinds of extrusion foods, such as snacks, breakfast cereal, core filling bars with honey, chocolate or cream in center, etc.

Why Choose Us?

1. Siemens motor

2. Siemens PLC and touch screen to control the whole line, all faults will display on the touch screen

3. ABB or Schneider electric parts

4. NSK bearings

5. All parts touch with raw materials or final products are made of stainless steel 304

6. 24V operation voltage, assure the safety of operators

7. Three kinds of protectors to keep machine and operator safe: over-heating, over-current, over voltage.

Snack extruder machine Flow Chart:

mixer→screw conveyer→SLG65 twin-screw extruder→hoister(air conveyer)→3-layer 5 meter roasting oven→single drum flavoring line→cooling machine→packing machine(optional).

Snack extruder machine Parameters:

Model | Installed Power | Real Power | Output | Dimension MM |

SLG65-III Snack Machine | 70kw | 40kw | 100-150kg/H | 22000x1200x2200 |

SLG70-III Puff Food Extruder | 90kw | 50kw | 200-240kg/H | 25000x1500x2200 |

SLG85-III Snack Food Equipment | 120kw | 100kw | 400-500kg/H | 30000x3500x4300 |

Commissioning & After-sales Service

1. We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc.

2. After receiving firm order and down payment, we start to apply for the Visa to your country immediately; while the machines arrives your factory, our engineers are ready to start for the commissioning service.

3. At buyer's request,1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4. Our engineers have responsibility to teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line..

5. Our engineers can provide basic formula for the production, and help the customer to produce good quality food according customer’s detailed formula.

6. It normally costs 10-14 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.