Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

Corn Flakes Processing Line Features

Corn flakes/breakfast cereals are a kind of breakfast with high nutritional value. They usually use corn powder and other cereals as main raw material, through mixing, extruding, flaking, drying, baking, coating and cooling, to get crispy flakes. It always service as breakfast cereal mixed with milk of coffee. But it can also be a kind of leisure snacks. This process line can also make other shapes of cereals such as rings, balls, chocos, curls etc

1. Raw materials: Corn powder and other cereals as raw materials.

2. Products: Corn flakes and other shaps of cereals such as rings balls chocos curls etc.

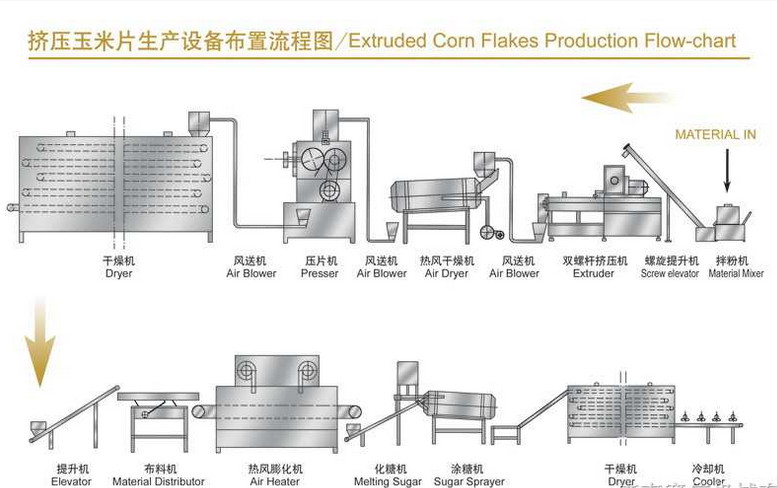

3.Equipment List :Mixer-Screw conveyor-Twin screw extruder-Air conveyor-Flaking Machine-Hoister-Drying oven -Hoister-Vibrate Feeder-Baking machine-Sugar Sprayer-Vibrate Feeder-Drying oven-Cooling Conveyor.

1.flour mixer: mainly using for mixing raw material, water and additives.

2.conveying: transporting mixed raw materials into the extruder. Shift time can be adjusted, also it is fully automated.

3.Extruding: raw material will be heated, extruded and puffed in this machine.

4.Pre-driving: dry the moisture products in a short period.

5. Sugar Sprayer: this equipment contains two parts roller and spraying system; its main function is to spray sugar on chocolate breakfast cereal.

6. Drying two: there is water in the sugar sprayed on breakfast cereal; this dryer can dry the breakfast cereal.

7.Cooling: chill the breakfast cereal after they are out of Drying two; crystallize the sugar liquid on breakfast cereal.

8.packing machine:packing the breakfast cereal.

4. Machines Materials:

| Model | Power | Output | Size |

| SLG65 Corn flakes machine | 90KW | 80-120KG/H | 39000*1200*2200mm |

| SLG70 Breakfast cereal processing line | 120KW | 150-200KG/H | 41000*1500*2200mm |

| SLG85 Corn flakes production line | 140KW | 300-400KG/H | 43000*3500*4300mm |

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.