Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

1.Fish feed manufacturing machine Details:

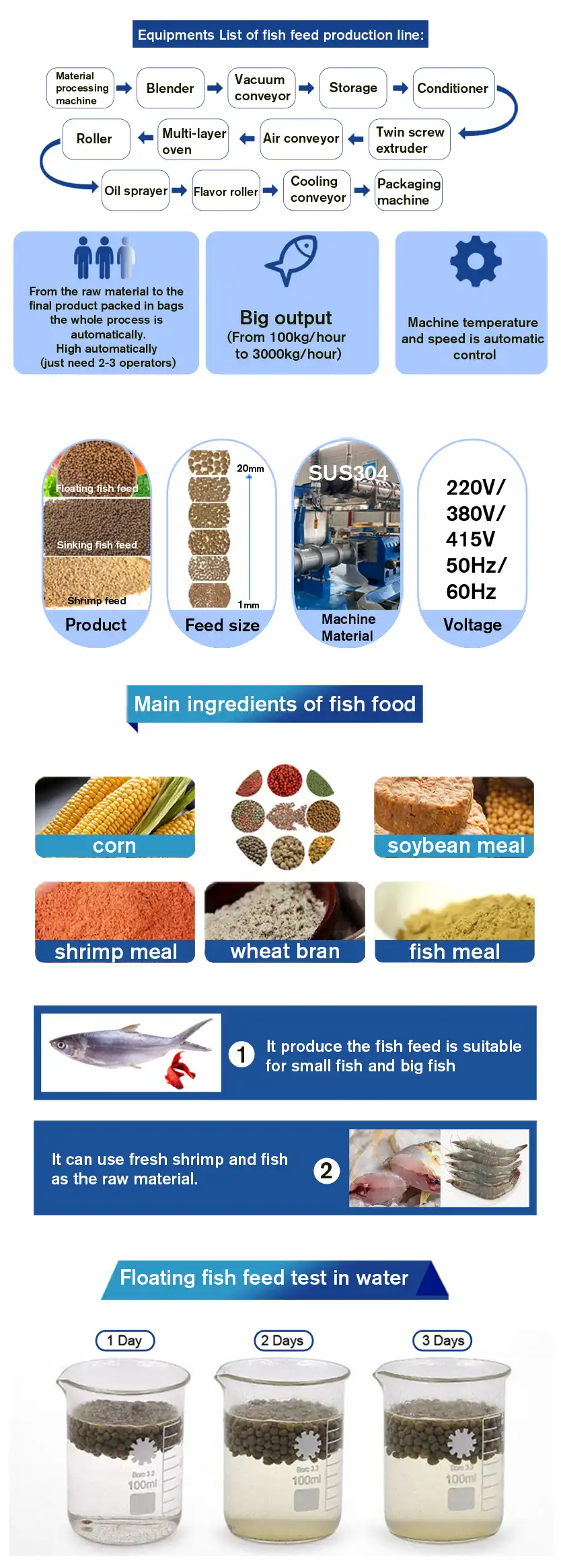

Twin Screw Automatic Floating Fish Feed pellet making extruder machine production line is deliberately made for special feed, which needs high in-shape rate and good-looking appearance. fish feed pellet processing plant is mainly used for sinking/floating/slow sinking fish feed. Effectively protect the aquaculture water body from pollution to improve the quality of life.

Automatic Fish Feed Extruder Production Machine Line

1. Floating Fish feed millmachine iswidely used forproducing grains into high-grade aquaticfeed pellets for fish, catfish, shrimps, crab etc.

2. The puffing fishfeed pellets can float on the watersurface without dissolution forover 12 hours.

3. It can produce different shapes feed for fish,dog,catetc.Forfish,thefeedcanbefloatingorsinking.

2.Technical Parameters of fish feed manufacturing machine:

ModelParameter | InstallPower(kw) | Consumption(kw) | Capacity(kg/h) | Dimension(m) |

SLG65 | 74 | 52 | 120-180 | 17*1.2*2.2 |

SLG70 | 95 | 70 | 200-300 | 20*1.5*2.2 |

SLG75 | 110 | 82 | 250-400 | 26*1.5*2.2 |

SLG85 | 139 | 104 | 400-800 | 28*3.5*4.3 |

SLG90 | 132 | 75 | 800-1200 | 28*3.5*4.3 |

3.Service

1. Help client to design the factory and offer professional advice and engineering drawing for the factory layout.

2. Report production progress regularly.

3. If the client can’t come to check the machine before delivery, Kelid helps the client check and make a testing report to show the details.

4. Provide user manual, factory inspection form, product certificate.

5. Provide 1-2 engineers to the client's factory for the installation and first-line workers' training.

6. After the installation, our engineer will assist you in on-site commissioning and personnel training (Training includes: equipment operation methods, precautions for use, equipment maintenance, etc.

7. Provide 13 months warranty and lifelong service.

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.