Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

1.Fish feed production plant Introduction:

The Floating fish feed machine can produce both floating and sinking feed pellets for fish, shrimp, crab, etc.Extruder forfish feed production processis deliberately made for special feed, which needs high in-shape rate and good-lookingappearance.fish feed production processis mainly used for sinking/floating/slow sinking fish feed. Effectively protect the aquaculture water body from pollution to improve the quality of life.

1. The motor of our extruder machine isSiemens Motor.

2. The raw material of pet food machines isStainless Steel.

3. Our automatic pet food machines are controled byfrequency changer,it is easy to operate.

4. Our factory will send our engineer toinstall machines for you.

5.pet food processing line have the12 monthsguarantee time.

6. Automatic Fish feed pellet machine is multi-function. Many types of snacks can be manufactured by changing the die head and model. animal feed.

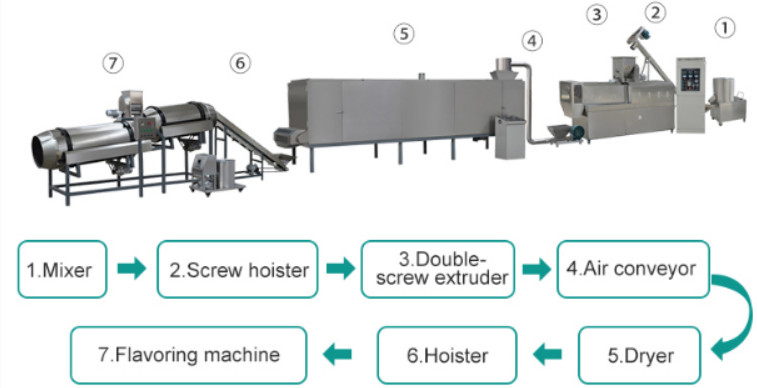

2.HOW IS FISH FOOD MANUFACTURED ?

Typical raw materials used in pet food processing include cereal flour, vegetable proteins, minerals and vitamins and, in some cases, meat or fish flour and fresh meat.

The dry ingredients enter the the pre-conditioner and are steam-hydrated. The counter-rotary twin shaft unit blends the ingredients and ensures proper mixing of steam, moisture and ingredients. Preconditioning produces partial gelatinization of starches and texturing of polymers

The partially cooked mixture is then fed to the twin-screw extruder. Shearing, internal temperature, pressure, moisture and residence times are accurately controlled to achieve optimum starch gelatinization without loss of food quality. Liquids or steam may be injected through ports in the extruder barrel at various processing stages. Degassing is possible at this stage using a vent-stuffer.

Granules are then shaped when they are extruded through the die. They are then put through a dryer, which reduces moisture (generally between 8 and 10%). The product is then coated, and flavoring and fat is added before cooling and packaging.

Model | SLG65 | SLG70 | SLG85 | SLG90 |

Installed Power | 80KW | 100KW | 180KW | 150KW |

Power Consumption | 40KW | 50KW | 90KW | 90KW |

Production Capacity | 100-150Kg/h | 200-250Kg/h | 400-600Kg/h | 800-1200Kg/h |

Dimension | 15000*1500*2200 | 20000*3500*2300 | 25000*3500*2300 | 30000*3500*2300 |

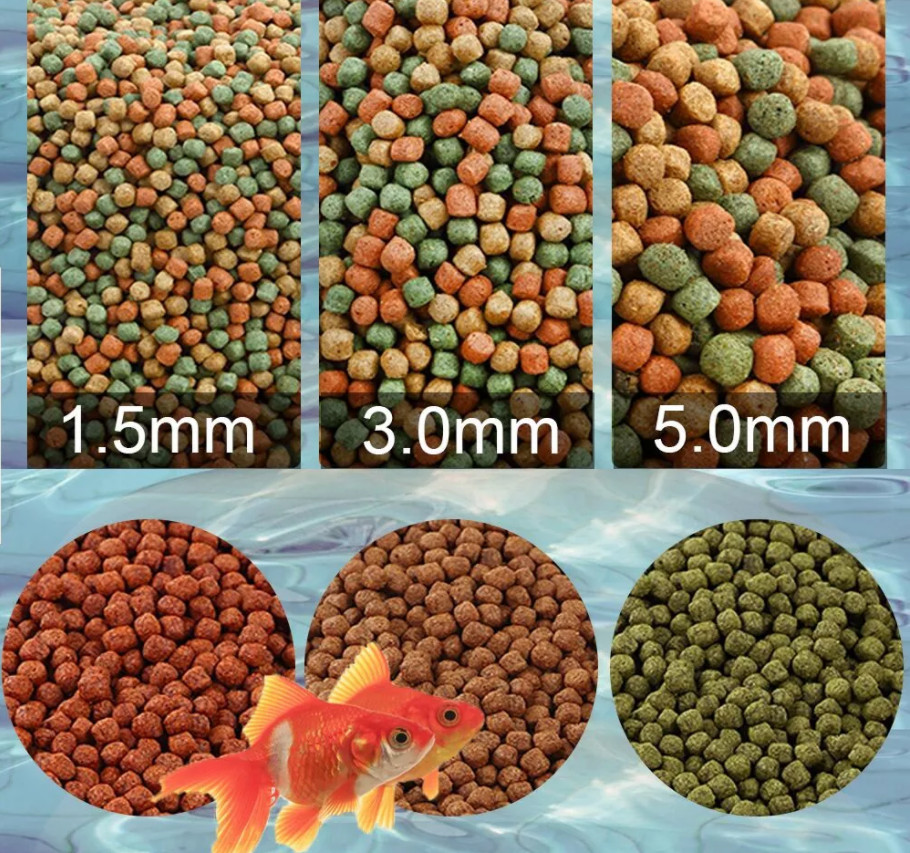

4.Fish food sample:

This floating fish feed machine price in nigeria can produce all kinds of animal food,such as dog food,cat food,fish food,bird food and so on.

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.