Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

1.Description of Animal food machine Feactures:

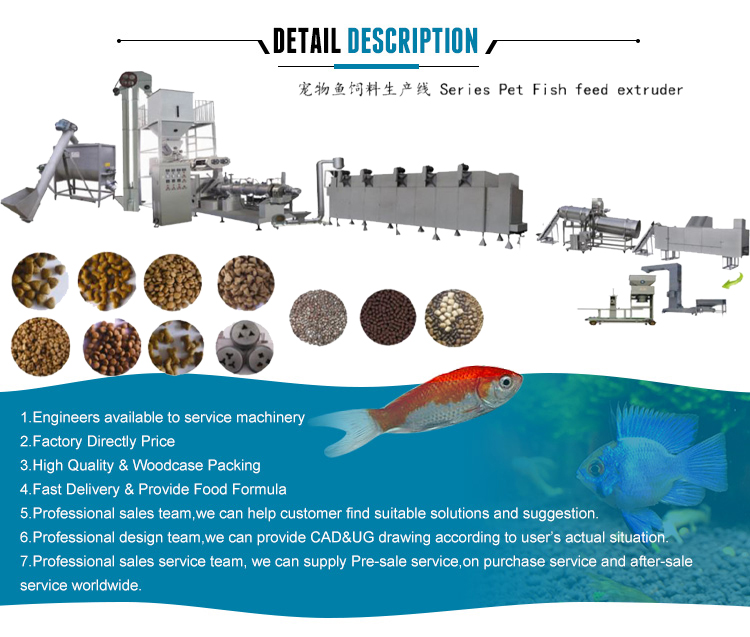

1).Our processing line adopt international advanced technology, the pellets size are very even.

2).we can adjust the cutter speed and the dies to get the different diameter and the length product

3).The Electric heating device system can control the temperature accurately

4).High temperature and high pressure can kill the salmonellosis andbacterial infections.

5).This Animal food machine can produce high-protein dog food.

6).This Animal food machine only need three workers

Mixer- Screw conveyor- Extruder- Air conveyor- Dryer- Air conveyor- Flavoring- Cooling Conveyor

① The raw material processing system of the production line. Its function is raw material pulverizing, weighing and mixing.

② The twin-screw extruder is used for curing, puffing, and forming raw material (There is a pre-conditioner contained in the extruder that is used for pre-conditioning and pre-heating the raw materials through steam, the raw materials are softened, which is more conducive to molding, and at the same time reduces the wear and tear of the raw materials to the extruder machine).

③ The Air conveyor is used to deliver fish feed from the extruder to the dryer.

④ The dryer is used to dry fish feed. According to the different energy sources, we have electric dryers, steam dryers, oil/gas dryers for you to choose from.

⑤ The Hoister is used to deliver fish feed from the dryer to the flavoring machine.

⑥ The flavoring machine is used to spray the surface of the fish feed with drugs for treating fish diseases and attractants, etc.

⑦ This is another Hoiser which is used to deliver fish feed from the seasoning machine to the cooling machine.

⑧ The Cooling machine is used to cool fish food before packing.

⑨ The Z Shape Hoister is used to deliver fish feed from the cooling machine to the packing machine.

⑩ The packing machine is used to pack fish food in different bags. We have fully automatic and semi-automatic packing machines for you to choose from. Powder, granular and blocky products can be packed by the packing machines.

2.Raw Material: Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

3.Products of Pet food processing machine :

| Animal dry dog cat food processing line making machine | |||||

| Model | SLG-65 | SLG-70 | SLG-85 | SLG-90 | SLG-95 |

Power installed | 74kw | 105kw | 130kw | 140kw | 165kw |

| Power consumption | 52kw | 75kw | 110kw | 125kw | 130kw |

| Capacity | 120-150kg/h | 220-260kg/h | 400-500kg/h | 800-1000kg/h | 1000-1500kg/h |

| Dimension(L*W*H) | 15*2*3m | 25*2*3m | 30*2*3m | 42*4*6m | 50*5*6m |

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.